Accelerator

DETAILED DESCRIPTION

Chemical Name | Appearance | Initial M.P. ℃ | Loss on drying % | Ash % | Residue on 150μm sieve % | Residue on 63μm sieve % | Application | |

|---|---|---|---|---|---|---|---|---|

CBS(CZ)

CAS NO: 95-33-0 | N-Cyclohexyl-2-benzothiazole sulfenamide

M.W. 264.4 | Gray-white powder/granule | ≥98.0 | ≤0.30 | ≤0.30 | ≤0.1 | ≤0.5 | A medium fast primary accelerator suitable for NR,IR,SBR,NBR, HR and EPDM. An outstanding delayed action accelerator. Top effective and safe when used at ordinary processing temperatures, causing no scorches. Vulcanized shows excellent physical property and quick complete. Usually used alone when activated by DPG, TMTD and TS. |

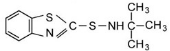

TBBS(NS)

CAS NO: 95-31-8 | O-Tertiarybutyl-2-benzothiazole sulfenamide P-

M.W. 238.37 | Gray-white powder/granule | ≥105.0 | ≤0.30 | ≤0.30 | ≤0.1 | ≤0.5 | Provide fast cure and high modulus in NR, SBR, BR and blends. Normally used alone or with small quantities of ultra accelerators in tire compounds or industrial rubber products. |

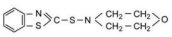

NOBS (MBS) CAS NO: 102-77-2 | N-Oxydiethylene-2-benzothiazole sulfonamide

M.W. 253.35 | Light yellow or orange crystal/granule | ≥80.0 | ≤0.30 | ≤0.30 | \ | \ | An excellent delayed accelerator. Similar as CBS with better scorch safety. Used in NR, IR, SBR, NBR and EPDM. Can be used alone or with other vulcanization accelerators such as thiurams, guanidines and dithiocarbamates to improve the activity. Mainly used in manufacture of tires, shoes and belts |

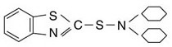

DCBS (DZ)

CAS NO: 4979-32-2 | N,N-Dicyclohexyl-2-Benzothiazole sulfenamide

M.W. 346.56 | Cream-colored granule | ≥97.0 | ≤0.30

| ≤0.30 | ≤0.1 | \ | A sulfenamide accelerator with excellent anti-scorching property and delayed onset of cure. Compatible with NR and synthetic rubbers, suitable for radial ply tyre and rubber belts. |

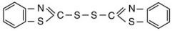

MBTS(DM)

CAS NO: 120-78-5 | Mercaptobenzothiazole disulfide M.W. 332.50 | Gray-white or light yellow powder/granule | ≥170.0 | ≤0.30 | ≤0.30 | ≤0.1 | ≤0.5 | A general purpose accelerator for sulfur cures. Unlike thiuram disulfides, MBTS doesn’t split off active sulfur during vulcanization. In natural and synthetic rubber processing. MBTS has a higher critical temperature than MBT, preventing early-cure and scorching. |

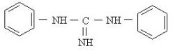

DPG (D) CAS NO: 102-06-7 | Diphenyl guanidine

M.W. 211.27 | Gray-white powder/granule | ≥145.0 | ≤0.30 | ≤0.30 | ≤0.1 | ≤0.5 | A non-staining, non-discoloring, secondary accelerator for thiazoles and sulfenamides in NR and SBR compounds. It exhibits better storage stability than thiurams and dithiocarbamates but is not as active. DPG can be used in latex as secondary gelling agent (foam stabilizer) in the silicoflouride foam process. |

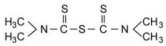

TMTM (TS) CAS NO: 97-74-5 | Tetramethyl thiuram monosulfide

M.W. 208.4 | Yellow powder/granule | ≥105.0 | ≤0.30 | ≤0.30 | ≤0.1 | ≤0.5 | A secondary accelerator with sulfenamides, thiazoles and guanidines; and provides improved processing safety when compared to other thiurams, high curing activity and no discoloration. An excellent accelerator for polychloroprene in association with DPG and Sulphur. |

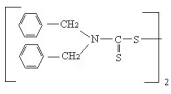

TBzTD CAS NO: 10591-85-2 | Tetrabenzylthiuram disulfide

M.W. 544 | Light yellow powder/granule | ≥128.0 | ≤0.50 | ≤0.30 | ≤0.1 | ≤0.5 | A fast curing primary or secondary accelerator for NR, SBR and NBR with long scorch times and low to nil nitrosamine generation during vulcanization. |

Chemical Name | Appearance | Initial M.P. ℃ | Loss on drying % | Ash % | Zinc content % | Residue on 150μm sieve % | Residue on 840μm sieve % | Application | |

|---|---|---|---|---|---|---|---|---|---|

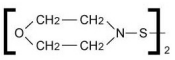

DTDM CAS NO: 103-34-4 | 4,4'-dithiodimorpholine

M.W. 236.27 | White crystal/granule | ≥120.0 | ≤0.30 | ≤0.30 | - | - | ≤0.00 | A sulfur donor vulcanizing agent for low sulfur or non-sulfur cure system; provides good heat aging resistance in NR and SR when used with sulfenamide accelerators. |

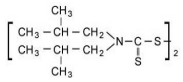

TiBTD CAS NO: 3064-73-1 | Isobutyl thiuram disulfide

M.W. 408.75 | Light yellow crystal/granule | ≥65.0 | ≤0.40 | ≤0.40 | - | - | ≤0.00 | Super accelerator and vulcanizing agent for NR,IR,BR,SBR,NBR and EPDM. Generates low level of relatively non-toxic nitrosamine, effective in latex as well as dry rubber. Cure ability is good but the strength is poor. |

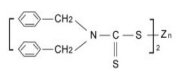

ZBEC(ZBDC ZTC)

CAS NO: 14726-36-4 | Zinc dibenzyl dithiocarbamate

M.W. 610.18 | White powder/granule | ≥180.0 | ≤0.50 | - | 10.0-12.0 | ≤0.1 | - | Safe-processing secondary accelerator. Can be used as primary in latex. High resistance to hydrolysis, low solubility in rubbers. Fast at higher vulcanization temperatures. It has longest anti-scorching capability in the dithiocarbamates. Used in NR, IIR, SBR, and EPDM. |

Tel: +0532-80903675

Tel: +0532-80903675 E-mail: sophia@crownchemical.com

E-mail: sophia@crownchemical.com 中文版

中文版

Add : 35th Floor, Qingdao International Finance Center, No.59.Middle HongKong Road, Qingdao, China 266071

Add : 35th Floor, Qingdao International Finance Center, No.59.Middle HongKong Road, Qingdao, China 266071 Tel : +0532-80903675

Tel : +0532-80903675 Fax : +86-532-8667 5300

Fax : +86-532-8667 5300 E-mail :sophia@crownchemical.com

E-mail :sophia@crownchemical.com