Antioxidant

DETAILED DESCRIPTION

Chemical name | Appearance | Softening point (°C) | Loss on drying (%) | Ash (%) | Heat loss (%) | Assay (GC) (%) | Solidifying point (°C) | Application | |

|---|---|---|---|---|---|---|---|---|---|

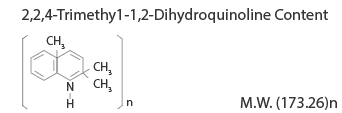

RD (TMQ) CAS NO. : 26780-96-1 |

| White to light yellow pieces/particles | Amber to light brown flake or granular | 80 - 100 | - | ≤ 0.30 | - | - | The alkyl of the p-teroctyl phenol formaldehyde viscosifying resin is in the counterpoint of the phenolic hydroxyl group, and no chemical reaction at the curing temperature, with non-thermal reactivity. |

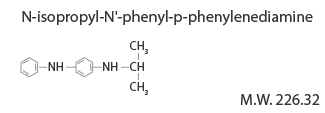

6PPD(4020) CAS NO. : 793-24-8 |

| White to light yellow pieces/particles | Grayish brown to brown granules | ≥ 45.0 | ≤ 0.50 | - | ≥ 96.0 | ≥ 45.5 | The resin with viscosification of tert-butyl formaldehyde will not have chemical reaction under curing temperature, which has non-thermal reactivity, excellent viscosification, and good compatibility with all kinds of rubber. It is an excellent viscosifying accelerator for all kinds of rubber. |

IPPD(4010NA) CAS NO. : 101-72-4 |

| White to light yellow pieces/particles | Dark brown to purple brown granules | ≥ 70.0 | ≤ 0.30 | - | ≥ 95.0 | - | Used as synthetic rubber and natural rubber adhesion promoter, especially for butyl benzene, nitrile, neoprene, suitable for high viscosity requirements of tire and rubber products, and easy to dissolve, no dust. |

Tel: +0532-80903675

Tel: +0532-80903675 E-mail: sophia@crownchemical.com

E-mail: sophia@crownchemical.com 中文版

中文版

Add : 35th Floor, Qingdao International Finance Center, No.59.Middle HongKong Road, Qingdao, China 266071

Add : 35th Floor, Qingdao International Finance Center, No.59.Middle HongKong Road, Qingdao, China 266071 Tel : +0532-80903675

Tel : +0532-80903675 Fax : +86-532-8667 5300

Fax : +86-532-8667 5300 E-mail :sophia@crownchemical.com

E-mail :sophia@crownchemical.com